How does cellulose insulation affect the environment?

We can all play an important role to fight climate change, reduce energy consumption and protect Earth’s natural resources for future generations. The insulation you choose for your home or building project can affect its carbon footprint. Keep reading to find out what qualities make cellulose insulation an excellent green building product.

Low-Energy Manufacturing

The environmental benefits of cellulose insulation do not start at the time the insulation is installed — they begin with production.

During manufacturing, some insulation materials require carbon-intensive processes and raw material sources such as refined oil. However, cellulose insulation is made from 85% recycled post-consumer paper. Furthermore, when added to walls, attics or ceilings, cellulose insulation can trap carbon for the life of the home.

SANCTUARY® by Greenfiber is made in electric-powered plants, using low-energy manufacturing processes. Fire retardants used in the insulation are considered to be of low or no toxicity. Improvements in fire-retardant processing and infusion technology have also resulted in historically low fire-retardant content with no loss of fire safety.

In addition to its lack of toxic chemicals or particles — including asbestos, mineral or glass fibers, PCBs and chlorofluorocarbons — SANCTUARY is considered eco-friendly because:

- Manufacturing with electric power uses 13 times less energy than fiberglass.1

- Greenfiber diverts 277,000 tons of paper from landfills each year, resulting in an environmentally friendly insulation material that locks in carbon equivalent to 157,000 acres of forest.2

- It has high energy-efficiency ratings.

- Converting trees into paper reduces landfill waste.

Plus, you can spend less on your attic sealing and insulation project by taking advantage of federal tax credits and utility rebates offered in some parts of the country. Beginning in 2023, the energy-efficient home improvement credit will be worth 30% of the total cost of eligible insulation projects up to $1,200 per year.

Short-Haul Transportation

Greenfiber’s supply chain is sustainably focused, with a plant in each region of the country. This keeps the delivery of raw materials and shipping of finished product to within a 500-mile radius of each plant, lowering resulting fuel emissions. This compressed packaging is also six times, or more, the nominal settled density for maximum transportation efficiency. This compressive packaging allows for fewer deliveries and more cellulose insulation on the transportation vehicle.

Reduced Global Warming Potential

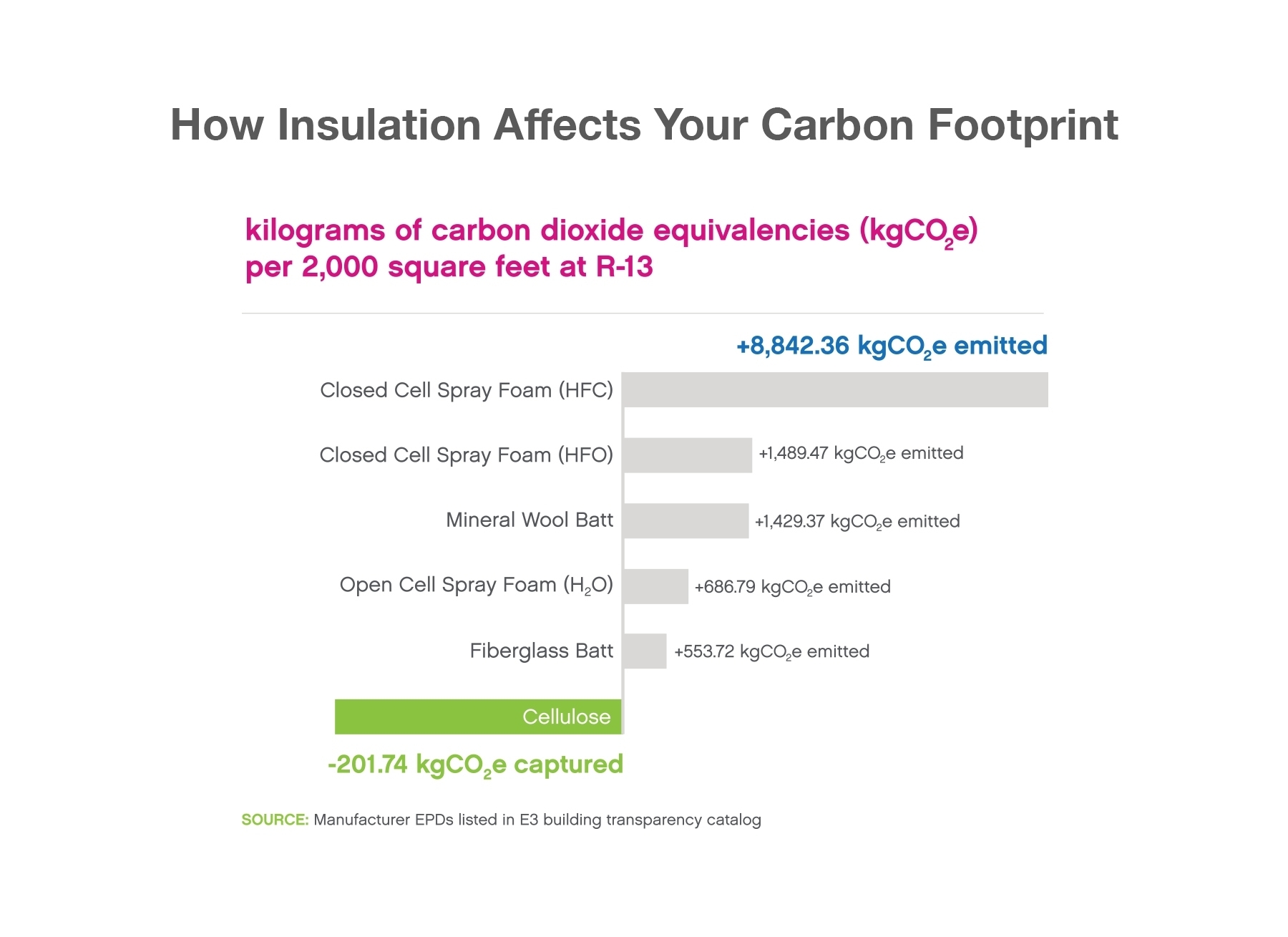

The most efficient zero-carbon homes are built using environmentally friendly insulation materials. One way of determining the global warming impact of different insulation materials is to compare their “global warming potential,” a metric used to measure the greenhouse gas emissions associated with a product from material extraction through end-of-life disposal or recycling (also known as embodied carbon).

Different insulation materials have a wide range of GWPs. Because it’s made from waste paper that is primarily carbon, SANCTUARY is the only major insulation material that reduces GWP. Want to see how? View our environmental product declaration.

Biodegradability

Increasing levels of carbon dioxide and other greenhouse gases in the atmosphere have raised worldwide concern regarding climate change. We normally think of forests as the natural “sink” for carbon dioxide. However, wood and paper products also serve to mitigate greenhouse gas emissions. These products offer long-term sequestering of carbon that would normally be released to the atmosphere by the processes of biodegradation or combustion, which negatively affects the environment.

Cellulose insulation interrupts the normal use/disposal/degradation cycle of paper by converting a throwaway product, such as old newspapers, into a durable building product that stores carbon for long periods — up to 100 years in some structures.

These tips can help in the effort of recycling:

- Keep the paper clean and separate from any food waste.

- Break down your cardboard boxes (you can leave the tape on unless it’s excessive).

- Recycle your newspapers, phone books, magazines, office paper, cardboard, cereal boxes, brown paper bags and construction paper — we’ll use that recycled material to manufacture SANCTUARY.

- Check with your waste management facility for guidelines.

Properties That Can Be Reused and Repurposed

Most construction projects have large dumpsters on-site full of construction waste and debris from building products that end up in the waste stream and require shipping to landfills, further affecting the environment.

In contrast, Greenfiber cellulose insulation is fully recovered and reused on-site when installed, leaving virtually no excess material to return to the waste stream. Special machines used in the blow-in process allow excess material to be vacuumed up and blown back in on-site or salvaged for a future installation.

Did you know you can even make papier-mâché with SANCTUARY? See how our customers repurpose cellulose insulation for fun projects at home. Our commitment to the environment is one more reason people can feel better about their choice of insulation. Follow the journey on our Sustainability page to see how Greenfiber is reducing carbon emissions that lead to global warming.

1 This comparison includes the production and energy used in the insulation manufacturing process. Based on the Sustainability Impact Index, - Pprepared by Principal Partners.

2 Based on the CIMA/CIMAC LCA for manufacturing and the WWF Biogenic Carbon Footprint Calculator for Harvested Wood Products. Tree sequestration statistics are based on the EPA Greenhouse Gas Equivalencies Calculator, https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator.

- Category: Sustainability